Sie möchten Ihr Werum PAS-X MES schnell einsetzen? Die Werum PAS-X Content Suite unterstützt Sie dabei durch Pakete mit vorkonfigurierten Inhalten.

Mit der Werum PAS-X Content Suite bereiten Sie PAS-X MES Systeme schnell für unterschiedliche Industriebereiche wie Pharma, Biotech oder Zell- & Gentherapie vor. Dafür bietet Ihnen unsere Content Suite vorparametrierte Inhalte, die Sie bei der Konfiguration Ihres individuellen Werum PAS-X MES Systems unterstützen. Zusammen mit unseren Beratern sowie Best-Practice-Inhalten für unterschiedlichste Einsatzbereiche implementieren Sie schnell ihre eigenen Geschäftsprozesse. Auf diese Weise gewinnen Sie Zeit und verringern Risiken.

Die Werum PAS-X Content Suite bietet Ihnen insgesamt 16 Content-Pakete für vier Einsatzbereiche:

- Administration Templates

- Process Libraries

- Integration Libraries

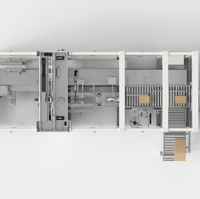

- Equipment Libraries